[metaslider id=”813″]

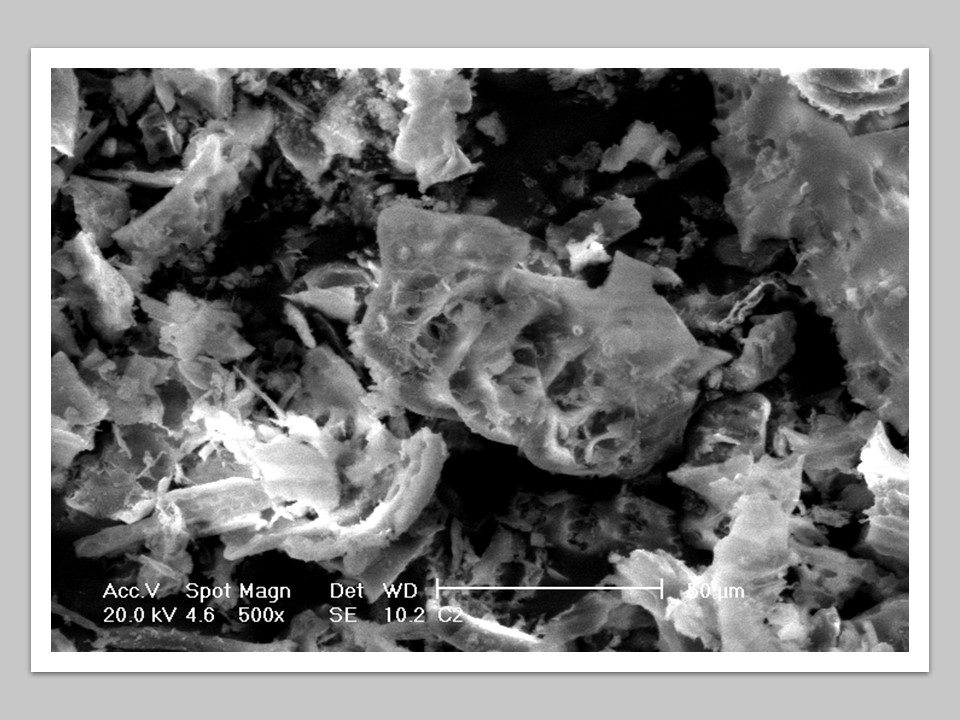

Rice husk is a major waste product of the rice-processing industries. Like most of the other biomass materials such as sugar, cane leaf, corn leaf, rice husk is also recognized as a potential source for energy generation from gasification or incineration processes. Acid leaching [1] and gasification [2] methods have been investigated for recovering silica from rice husk. Of all the plant residues, the ash of rice husk contains the highest amount of silica (SiO2). The burning of rice husk in air results in the formation of rice husk ash (RHA) with SiO2 content of 85% to 98% depending on the burning condition, furnace type, rice variety, moisture content, weather and geographic area [3].

RHA is available in abundance at no cost. The presence of silica in RHA is known since 1938 and extensive literature have reported the uses of RHA as silica replacement for the production of silicon-based materials in industrial and technological applications [4-9]. Some small amounts of inorganic impurities are usually present in the ash together with unburned carbon. The unburned carbon can be removed from the ash by further heating at high temperature; however high temperature usually leads to the crystallization of the amorphous silica to cristobalite and/or tridymite [10]. The crystallization of silica in RHA occurs when the burning conditions of husk are uncontrolled [4]. The crystallization form of silica has drawbacks towards the preparation of silicon-based materials since silica ash is inactive in its crystalline form [4, 11]. Highly reactive silica in RHA can be produced by maintaining the combustion temperature below 500 °C under oxidising conditions for a relatively long period or high temperature up to 680 °C for less than one minute [5]. In addition, the combustion environment affects the specific surface area of silica, hence temperature and environment must be considered in the pyro-processing of rice husk to produce ash with a maximum reactivity of silica [10]. However, silica in RHA can remain in the amorphous form if the combustion temperatures up to 900 °C for less than an hour, whereas crystalline silica can be produced at 1000 °C when heated for more than 5 minutes [6].

However, silica can be easily extracted at a low temperature of 40 °C because of the amorphous nature of silica in RHA. Amorphous silica in RHA can be extracted using low-temperature alkali extraction since the solubility of amorphous silica is very low at pH below than pH 10 and it increases sharply above pH 10. The unique solubility behaviour of amorphous silica enables it to be extracted in pure form from RHA by dissolution under alkaline conditions [12]. This low energy method based on alkaline solubilization of amorphous silica can be cost-effective compared to the current smelting method. Hence, it provides lower alternative energy compared to the current high energy method. The development of a simple low energy chemical method for producing pure silica from rice husk has lead to a variety of industrial applications for RHA.

References:

- Kalapathy, U., Proctor, A. and Shultz, J. Simple Method for Production of Pure Silica from Rice Hull Bioresour. Technol. 2000. 73(3): 257-262.

- Luan, T. C. and Chou, T. C. Recovery of Silica from the Gasification of Rice Husk/Coal in the Presence of a Pilot Flame in a Modified Fluidized Bed. Eng. Chem. Res. 1990. 29: 1922–1927.

- Lanning, F.C. Silicon in Rice. Agric. Food Chem. 1963. 11: 435-437.

- Hamdan, H., Muhid, M. N. M., Endud, S., Listiorini, E. and Ramli, Z. 29Si MAS NMR, XRD and FESEM Studies of Rice Husk Silica for the Synthesis of Zeolites. Non-Cryst. Solids. 1997.211(1-2): 126-131.

- Mehta, P.K. Siliceous Ashes and Hydraulic Cements Prepared Therefrom. S. Patent 4,105,459. 1978.

- Nehdi, N., Duquette, J. and Damatty, A. E. I. Performance of Rice Husk Ash Produced Using Admixture in Concrete. Concr. Res. 2003. 33(8): 1203-1210.

- Yalcin, N. and Sevinc, V. Studies on Silica from Rice Husk. Ceram. Int. 27: 219-224.

- Prasad, C. S., Maiti, K. N. and Venugopal, R. Effect of Substitution of Quartz by Rice Husk Ash and Silica Fume on the Properties of White ware Compositions. Ceram. Int. 29(8): 907–914.

- Bhattacharya, A. K., Naiya, T. K., Mandal, S. N. and Das, S. K. Adsorption, Kinetics and Equilibrium Studies on Removal of Cr (VI) from Aqueous Solutions Using Different Low Cost Adsorbents. Eng. J. 2008. 137(3): 529-541.

- Krishnarao, R. V., Subrahmanyam, J. and Kumar, T. J. Studies of the Formation of Black Particles in Rice Husk Ash. Eur. Ceram. Soc. 2001. 21(1): 99-104.

- Payá, J., Monzó, J., Borrachero, M. V., Mellado, A. and Ordoñez, L. M. Determination of Silica in Rice Husk Ash by a Rapid Analytical Method. Concr. Res. 2001. 31(2): 227-231.

- Kamath, S.R. and Proctor, A. Silica Gel from Rice Hull Ash: Preparation and Characterization. Cereal Chem. 75: 484–487.

Source: Nor Suriani Sani (2009). Synthesis and Characterization of Alcohol-Free Tyrosinase Encapsulated Silica Aerogel. MSc (Chemistry), Master Thesis, Universiti Teknologi Malaysia.