The number of floor problems that BRE investigates seems disproportionately large when compared to problems occurring in other, more complicated building elements. Their relative simplicity can often mean that floors are overlooked, and project timescales tend to leave them to the last minute. But a defective floor can have a huge impact on the operation of a building, and putting it right can cause long delays to the project and may incur large unavailability charges. Following best practice guidance can avoid such delays.

Floors are deceptively simple and their proper design is often overlooked. This sometimes leads to the installation of floors that are inappropriate or inadequate for their intended use, or floors that cannot be installed in the timescale that has been allowed.

The most common flooring type that BRE investigates is resilient floor coverings, such as sheet vinyl, rubber or linoleum. Typical problems include:

- failed welded seams

- ridges appearing across thresholds or corridors

- bubbles or blisters in highly trafficked areas.

The last of these is by far the most common mode of failure. The floor covering de-bonds from the screed, sometimes creating a ‘dome’ in the floor.

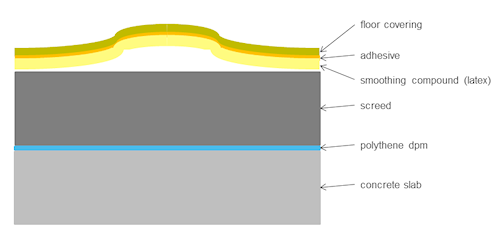

This is usually caused by dampness in the screed, affecting the smoothing compound beneath the flooring. When left in damp conditions for a long period, some smoothing compounds break down into a white powder called ettringite. This powder has no inherent strength and the bond between the floor covering and the screed is lost. Subsequent foot or trolley traffic over the flooring will cause it to stretch and deform.

To avoid this, the level of dampness in the screed must be measured accurately before the floor coverings are laid. If the relative humidity in the screed is above 75%, a liquid damp-proof membrane must be applied to the screed, or the screed should be allowed to dry.

Source: BRE Group: Why is it so hard to get the floor right?