Concrete are tested for two main purposes, for control of quality and to check its compliance with specifications. The non-destructive testing (NDT) of hardened concrete is carried out to test the in-situ strength of concrete structures. A few non-destructive tests have been devised to measure concrete properties without destroying the structures.

In general these non-destructive testing are carried out during and after construction. When construction is in progress, tests are carried out if there are doubts on the quality of works. It is also useful in determining the strength before false work could be removed safely or in avoiding premature loading. Non- destructive testing may be used during service for instance in rehabilitation and repair works where obvious signs of structural failures like cracks, deflection, rusting of steel bars were detected.

Three types of non-destructive tests will be carried out in the laboratory consisting of:

- Electromagnet Cover meter

- Rebound Hammer test (Schmidt’s hammer)

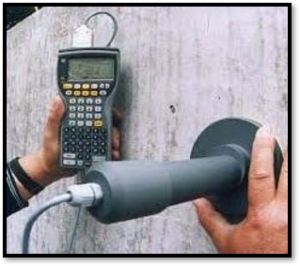

- Ultrasonic Pulse Velocity Test (Pundit Test)

1) Watch the lecture video

2) Presentation Slides

Loading…

Loading…

3) Answer the Questions

From your lab results, answer all the questions below:

1) Determine the strength of concrete from the rebound numbers and the pulse velocity.

2) Calculate the followings:

a) Standard Deviation (SD)

b) Coefficient of Variance (CV)

c) Ultrasonic Pulse Velocity (UPV)

3) Compare the results of the concrete strength from the rebound numbers and the pulse velocity. Discuss on the results

4) Other References and Videos (click the links below)

1. Types of Non-Destructive Testing

2. The Importance of Non-Destructive Testing

3. 13 Non-Destructive Testing of Concrete

4. Non-destructive Testing of Concrete Journal

5) NDT Youtube Videos below: