PROF. DR. MAT UZIR WAHIT

RESEARCH PROJECTS

My research projects have been focused on the natural fibre composite materials, rubber-toughened polymer, polymer nanocomposites, cellulose nanocomposites, biomaterials – including biodegradable polymers and shape memory polymer.

List of Current Projects:

1. MECHANICAL, THERMAL AND MORPHOLOGICAL PROPERTIES OF RECYCLED POLYETHYLENE TEREPHTHALATE/RECYCLED POLYPROPYLENE REINFORCED HYBRID KENAF FIBER/MONTMORILLONITE COMPOSITES

The feasibility of developing kenaf fiber (KF) reinforced recycled polyethylene terephthalate (rPET) and recycled polypropylene (rPP) with comparison to two different reinforcing fillers, KF and montmorillonite (MMT) reinforced rPET/rPP was studied. In addition, the compatibilizer of ethylene vinyl acetate grafted maleic anhydride (EVA-g-MA) at composition 5 phr was used. Composites were prepared using twin-screw extruder and followed by injection molding. The optimum blend ratio of rPET/rPP was observed at 90 wt% rPET and 10 wt% rPP. The incorporation of 5 phr EVA-g-MA improved tensile and impact strength of the blends. Scanning electron microscopy (SEM) micrographs revealed that by adding EVA-g-MA, homogeneous dispersion of rPP was observed. The addition of KF into compatibilized blend decreased mechanical properties of tensile and impact strength of the blends while adding MMT improved significantly the mechanical properties. The addition of MMT into rPET/EVA-g-MA/rPP/KF blends increases mechanical properties of the blends. This improvement is believed due to the main constituent in the layered structured of MMT. It is worthy to note that MMT consists of two silica (Si=O) sheets with the presence of alumina (Al-OH) sheet in between those silica sheets. Hence, in general, all clays have hydroxyl groups on their surface which appears to improve interfacial interaction and bonding between each material in the blends. It is believed that hydrogen from Al-OH clay can forms hydrogen bond with lone pair electron of carbonyl oxygen in MA from EVA-g-MA, and/or carbonyl oxygen in rPET chain. Meanwhile, lone pair electron of oxygen from Si=O clay can forms hydrogen bond with hydrogen from hydroxyl group of cellulose, and/or hydrogen from hydroxyl end group of rPET.

Figure 1: Proposed chemical interaction between rPET, rPP, EVA-g MA, KF, and MMT

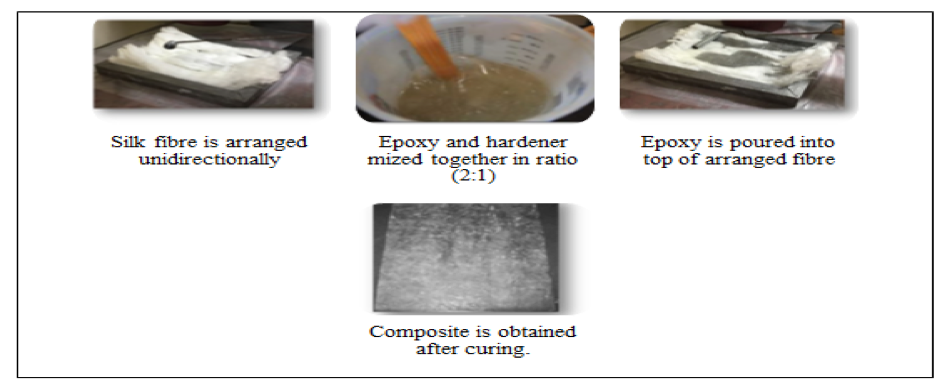

2. ENHANCED DUCTILITY AND STRENGTH OF MICRON SILK FIBROIN FIBERS REINFORCED EPOXY COMPOSITES

Natural fiber reinforced composites have recently been investigated with considerable interest in research, due to their advantages such as high specific strength, low density, promising biodegradability and environmental friendliness. Generally, plant fibres (e.g. flax, hemp and jute, kenaf, oil palm) has been used to reinforced composites and have been the focus of natural fibres composites. However,animal-sourced fibres (such as silkworm and spider silk ) have seldom found to be utilised as composite reinforcements. Silk from domestic silkworm, Bombyx mori is highly crystalline in the molecular structure and stands as the only continuous filament of natural fibrous fibre. Silk has attracted attention of researcher nowadays as new filler/reinforcer in polymer matrix. Few studies has been focused on woven and non woven silk fibroin (SF) fiber/epoxy composites however the general effect of short silk fiber as reinforcements to improve the mechanical properties of polymer and composites has not been studied extensively. SF fibers with various lengths (1mm, 500 micrometer, 1 micrometer) will be prepared by hydrolyzing degummed in alkali solution. SF fibers/epoxy composites will be prepared by vacuum infusion technique. The mechanical behavior of the composites will be studied specifically on tensile, flexural, Izod impact and dynamic mechanical analysis. The thermal properties of the composites will be based on differential scanning calorimetry and thermogravimetric analysis. From this study, it is expected that the SF/epoxy composites enhance the mechanical performance by incorporating the natural silk fibroin fibers.

Figure 1: Fabrication of silk fibre reinforced epoxy composite using the hand lay-up technique.

3. DEVELOPMENT OF CROSSLINK POLYETHYLENE (XLPE) NANOCOMPOSITES: MECHANICAL AND THERMAL PROPERTIES CHARACTERIZATION AND ANALYSIS

This project focuses on the development of crosslink polyethylene (XLPE)/aluminium oxide (Al2O3) nanocomposites as a function of filler concentration by direct melt compounding using a conventional twin screw extruder and injection molded into the standardized specimens. The filler concentration will be varied from 0-10 wt%. The and nanocomposites of XLPE as a function of filler type such as silica dioxide (SiO2), titanium dioxide (TiO2),zinc oxide (ZnO) and clay will also be developed with same filler concentration of 5 wt%. The investigation will also be conducted on XLPE/Al2O3/clay ternary hybrid systems of Al2O3 and clay in 1:1and 2:1 ratios.

Figure 2: Example of XLPE cable.

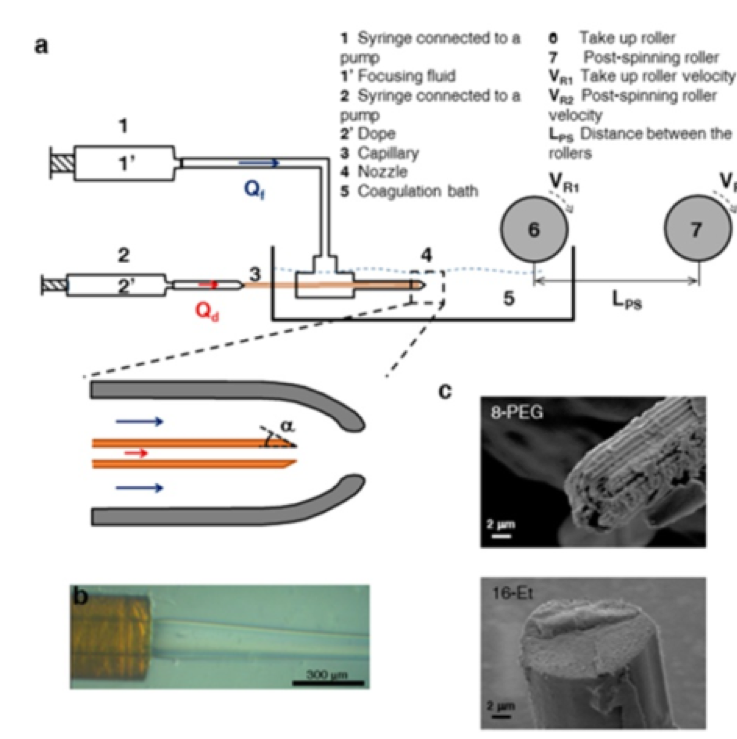

4. ALIGNED HIGH PERFORMANCE SILK FIBRE, KEVLAR-49 FIBRE AND E-GLASS FIBRE REINFORCED EPOXY COMPOSITES: SYNTHESIS AND COMPARATIVE STUDY ON THE CHARACTERISTIC OF COMPOSITES

Natural fibre reinforced composites have recently been investigated with considerable interest in research, due to their advantages such as high specific strength, low density, promising biodegradability, and environmental friendliness. Generally, plant fibres have been used to reinforced composites and have been the focus of natural fibres composites. However, animal-sourced fibres (such as silkworm and spider silk) have seldom found to be utilised as composite reinforcements. Silk from domestic silkworm Bombyx mori (B. mori) is highly crystalline in the molecular structure and stands as the only continuous filament of natural fibrous fibre. Silk has attracted attention of researcher nowadays as new reinforce in polymer matrix. Here, a high performance silk fibre (HPSF) will be produced from a new bioinspired approach called straining flow spinning (SFS). This new approach is inspired in the flow focusing technology that controls the flow of a fluid. SFS is shown to be a robust and versatile spinning technology found in natural spinning glands. This HPSF fibre which is expected comparable with synthetic fibres such as Kevlar-49 and E-glass fibre. The mechanical properties of the single strand fibre of HPSF are similar to the Kevlar-49 and E-glass. However, there is no study specifically on HPSF reinforced epoxy composite and also study on comparative properties between HPSF, Kevlar-49 and E-glass fibres reinforced epoxy composites. These composites will be prepared by vacuum infusion technique. This study will be an interesting study since it will discover what influence these high performance fibres as reinforcement into epoxy composites. Fibres with different loading and different orientation (0 deg; and 90 deg;) will be used into epoxy composites. The mechanical and thermal behaviour of the composites will be explored and studied. From this study, it is expected that the HPSF reinforced epoxy composites has comparable mechanical performance with Kevlar-49 and E-glass fibre.

Figure 3: Scheme of the straining flow spinning process and fibres spun with this technique. (a) Schematic representation of the straining flow spinning technique including its main elements. The inset shows the detail of the capillary-nozzle system. (b) Image of the dope jet exiting the capillary. The outlet of the nozzle would be located on the right out of the field of the micrograph. (c) Representative SEM images of the fracture of SFS spun fibres. Scale bar = 2 µm.

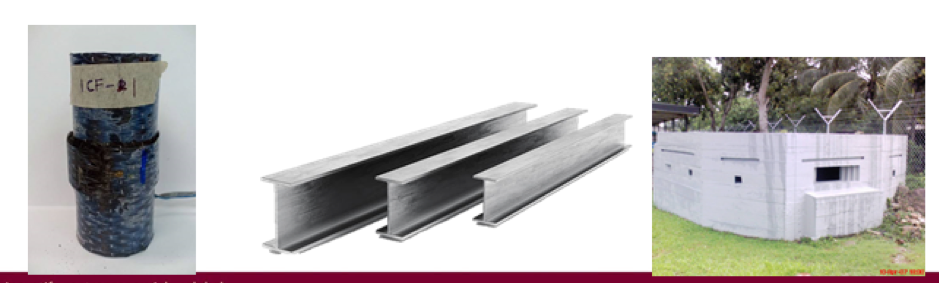

5. INVESTIGATING THE POTENTIAL USED OF TIN SLAG POLYMER CONCRETE FOR STRUCTURAL APPLICATION

Polymer concrete (PC), also known as synthetic resin concrete and plastic resin concrete, posed high structural engineering properties. PC is valued for its high compressive strength, chemical resistance, short curing time and impact resistance. Tin slag considered a potential material that can be proposed in the civil construction field as an aggregate for PC production to reduce the consumption of natural resources. Further research is highly encouraged to investigate the potential research area between the concrete structure and properties changes in relation to particle and surface characteristics. The previous study reported has focused on the shape, size, physical and mechanical properties of tin slag to assess its suitability for road pavements. However, the structural performance of the PC due to the effect of particle sizes and long-term durability needs to be investigated. Therefore the aim of this study is to determine the potential of using tin slag PC (TSPC) structure in relation to long-term tropical weathering exposure. A novel way is to incorporate tin slag in polyester to prepare PC by adopting a range of aggregate grading i.e. gap-graded, open graded, well graded and uniformly graded to identify the impact on mechanical properties. The depth of range of studies which required to be made in respect of aggregate to understand their widely varying effect and influence on properties of concrete such as compressive strength and durability. A field experiment will be carried out to investigate the effect features such as mechanical behavior, moisture ingression, creep, acidic and UV degradation due to laboratory and outdoor and aggressive environment exposure conditions. The expected finding could provide feasibility on sustainability and performance scale for it to be accepted as structural grade material for PC.

Figure 4: Potential application of tin slag polymer concrete outdoor application (eg: column, beam, bunker and etc).

6. A STRATEGY AND MECHANISM OF FABRICATING RAMIE FIBER REINFORCED EPOXY COMPOSITE WITH IMPROVING THERMAL AND MECHANICAL PROPERTIES

Natural fiber reinforced composites have recently been investigated with considerable interest in research, due to their advantages such as high specific strength, low density, promising biodegradability and environmental friendliness. Generally, plant fibres (e.g. flax, hemp and jute, kenaf, oil palm) has been used to reinforced composites and have been the focus of natural fibres composites. In this study, ramie fiber (RF) will be used as reinforcement in composite polymers and showed to have good mechanical properties compared to other types of natural fiber. A strategy method need to be emphasized to optimize of composite manufacturing process which is an important means for improving mechanical properties and thermal properties of natural fiber composites. In this project, short ramie fiber (RF) was respectively, modified by alkaline and silane treatment and then composite will be prepared using vacuum infusion process technique Few studies have been focused on long ramie and ramie yarn fiber /epoxy composites however; general effect of short silk fiber as reinforcements to improve the mechanical properties of composites has not been studied extensively. RF fibers with various lengths (5mm, 1mm, & 500micron) and different ramie fiber content of RF fibers/epoxy composites will be prepared by vacuum infusion technique. The mechanical behavior of the composites will be studied specifically on tensile, flexural, Izod impact and dynamic mechanical analysis. The thermal properties of the composites will be based on differential scanning calorimetry and thermogravimetric analysis. The comparison with the ramie fiber without treatment was also done. It is expected that treated ramie fiber has better mechanical and thermal properties than the untreated one.