Showing the sample of Teflon gasket been used for the electrolyzer

electrolytes used for the study are copper chloride dissolved in hydrochloric acid for anodic and hydrochloric acid for cathodic

hydrogen production using hybrid membrane from PBI based is only 1/4 from the cost of using Nafion membrane

1 journal article with an impact factor of 4.939, quartile 2 in journal citation report (JCR2019) ISI, 2 Scopus journal articles, and 1 book chapter have been published from this study. This project was also awarded the 1st runner for the best poster category in the International Conference on Fuel Cell & Hydrogen Technology (ICFCHT2017)

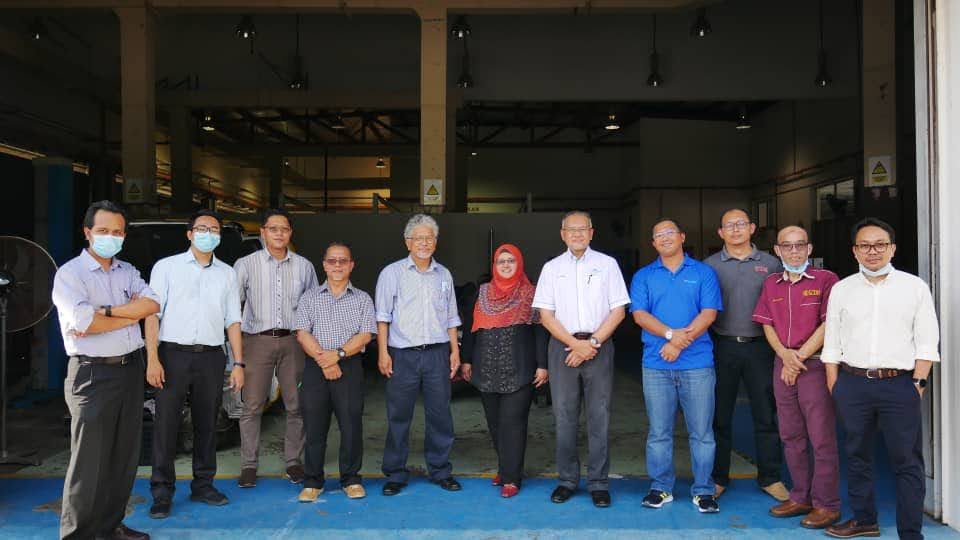

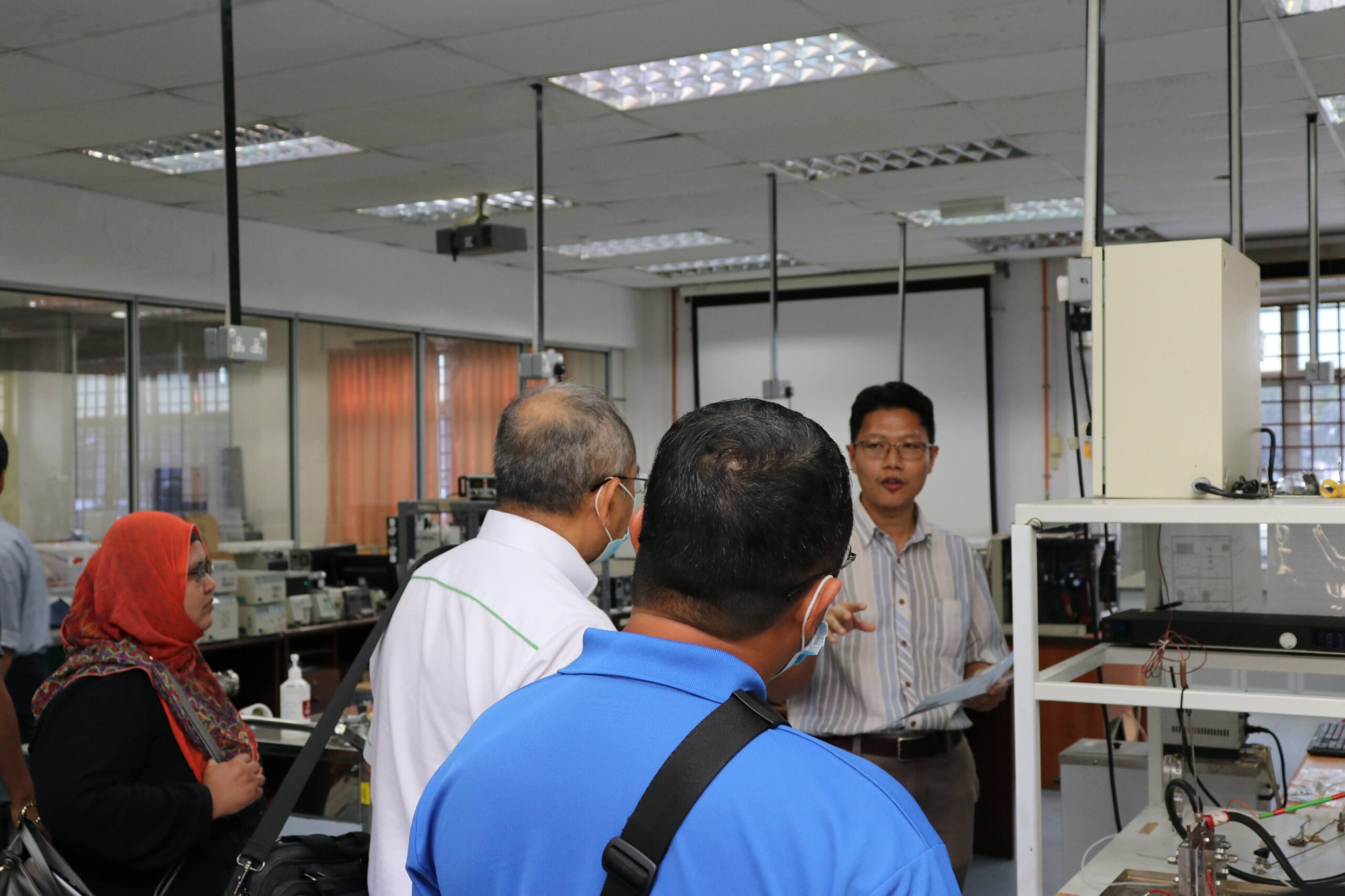

Showing the experimental setup for high temperature of CuCl electrolysis using proton exchange membrane (PEM) for hydrogen production to MGTC’s CEO and delegates