Laser Surface Alloying

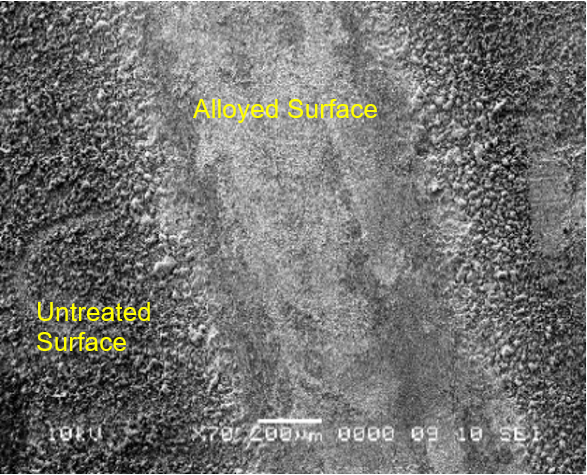

Modifying the surface properties of a material by melting it with a laser beam and adding one or more elements to create a new alloy with improved properties such as wear resistance, corrosion resistance, and hardness.

Laser surface alloying is a technique that enhances the surface properties of materials by introducing alloying elements through laser processing. This method improves characteristics such as wear resistance, corrosion resistance, and hardness, making it valuable in various industrial applications.

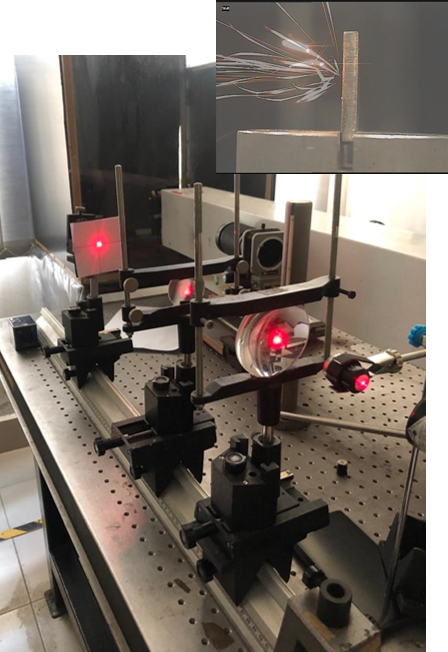

Our system utilizes a CO₂ laser with a maximum output of 100W, providing sufficient energy to melt the substrate surface and facilitate the incorporation of alloying elements. The laser beam is precisely controlled using stepper motors, enabling accurate manipulation of the laser’s position and movement across the material’s surface. This mechanical control ensures uniform alloying and consistent surface modification.

The integration of a high-power CO₂ laser with stepper motor control allows for precise and efficient laser surface alloying. This setup is suitable for enhancing the surface properties of various materials, including metals and alloys, thereby extending their service life and performance in demanding environments.