Recent Research

Ts. Dr. Muhammad Safwan Abd AzizRecent Research Work

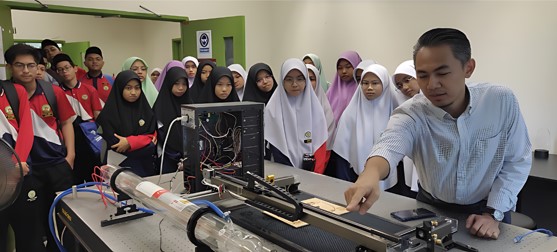

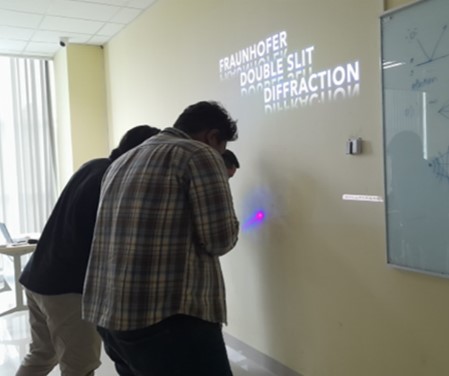

Physics governs many phenomena in the universe, from the smallest particles to the vastness of space. Therefore, teaching physics requires not only a deep understanding of these principles but also the ability to convey them in a way that inspires curiosity and critical thinking. My teaching philosophy is built on the belief that education in physics should be an engaging, inclusive, and transformative experience. I strive to create a learning environment where students are not merely passive recipients of knowledge but active explorers of the physical world. My goal is to ignite a passion for discovery in my students, encouraging them to question, experiment, and

Contact Me ?

05-07 Level 5, Block T05,

Laser Center, Faculty of Science,

Universiti Teknologi Malaysia,

81310 Skudai, Johor

safwanaziz@utm.my

phone: (+6) 07-561-0349