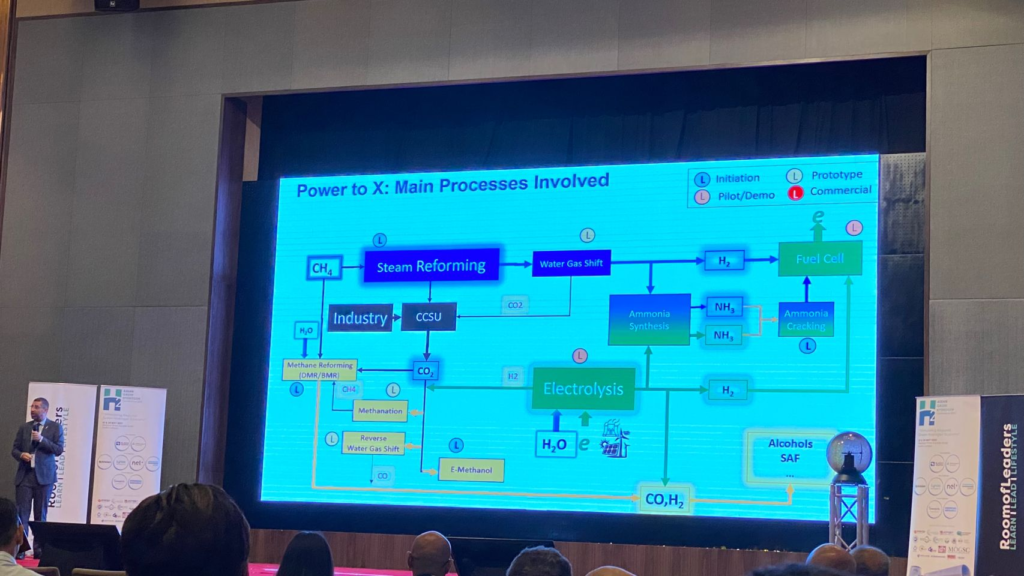

𝐄𝐥𝐞𝐜𝐭𝐫𝐨𝐥𝐲𝐳𝐞𝐫𝐬 are devices that use 𝐞𝐥𝐞𝐜𝐭𝐫𝐢𝐜𝐢𝐭𝐲 to 𝐬𝐩𝐥𝐢𝐭 𝐰𝐚𝐭𝐞𝐫 (𝐇𝟐𝐎) 𝐢𝐧𝐭𝐨 𝐡𝐲𝐝𝐫𝐨𝐠𝐞𝐧 (𝐇𝟐) 𝐚𝐧𝐝 𝐨𝐱𝐲𝐠𝐞𝐧 (𝐎𝟐) through 𝐞𝐥𝐞𝐜𝐭𝐫𝐨𝐥𝐲𝐬𝐢𝐬 𝐩𝐫𝐨𝐜𝐞𝐬𝐬.

There are four main types of electrolyzers used for hydrogen production:

1. 𝐀𝐥𝐤𝐚𝐥𝐢𝐧𝐞 𝐞𝐥𝐞𝐜𝐭𝐫𝐨𝐥𝐲𝐳𝐞𝐫𝐬: These electrolyzers use a liquid electrolyte, typically a solution of potassium hydroxide, to conduct electricity between the two electrodes. Alkaline electrolyzers have been in use for many decades and are widely used in large-scale industrial applications. They are efficient and relatively low cost, but they have a limited ability to operate at high current densities.

2. 𝐏𝐨𝐥𝐲𝐦𝐞𝐫 𝐞𝐥𝐞𝐜𝐭𝐫𝐨𝐥𝐲𝐭𝐞 𝐦𝐞𝐦𝐛𝐫𝐚𝐧𝐞 (𝐏𝐄𝐌) 𝐞𝐥𝐞𝐜𝐭𝐫𝐨𝐥𝐲𝐳𝐞𝐫𝐬: These electrolyzers use a solid polymer electrolyte membrane to separate the anode and cathode, which allows for higher current densities and better efficiency than alkaline electrolyzers. PEM electrolyzers are smaller and more compact than alkaline electrolyzers, making them well-suited for on-site hydrogen production.

3. 𝐒𝐨𝐥𝐢𝐝 𝐨𝐱𝐢𝐝𝐞 𝐞𝐥𝐞𝐜𝐭𝐫𝐨𝐥𝐲𝐳𝐞𝐫𝐬: These electrolyzers operate at high temperatures (typically above 800°C) and use a solid oxide ceramic electrolyte to separate the anode and cathode. Solid oxide electrolyzers can operate at high current densities and have high efficiency, but they are also more expensive and require high operating temperatures.

4. 𝐀𝐧𝐢𝐨𝐧 𝐄𝐱𝐜𝐡𝐚𝐧𝐠𝐞 𝐌𝐞𝐦𝐛𝐫𝐚𝐧𝐞 (𝐀𝐄𝐌) 𝐞𝐥𝐞𝐜𝐭𝐫𝐨𝐥𝐲𝐳𝐞𝐫𝐬: These electrolyzers use a solid anion exchange membrane to conduct hydroxide ions from the cathode to the anode, where they combine with water to form oxygen and hydrogen gas. AEM electrolyzers are a relatively new technology that is still under development, but they offer several potential advantages over other types of electrolyzers. AEM electrolyzers are also capable of producing high-purity hydrogen without the need for expensive purification systems. However, AEM technology is still in the early stages of development and has not yet been widely commercialized. As research and development continue, AEM electrolyzers could become a promising technology for hydrogen production.

The choice of electrolyzer technology depends on a variety of factors, including the required hydrogen production rate, operating conditions, and capital and operating costs. Each technology has its own advantages and disadvantages, and the optimal choice depends on the specific application.

#energy#technology#hydrogen#research#development