The CEO of Malaysian Green Technology and Climate Change Centre Visited Institute of Future Energy UTM

The Institute of Future Energy (IFE), Universiti Teknologi Malaysia (UTM) Johor Bahru was honored to receive a visit from a special guest, the CEO of Malaysian Green Technology & Climate Change Centre (MGTC) Mr. Shamsul Bahar Mohd Nor on 9th August 2020.

During the visit, Mr. Shamsul Bahar was accompanied by other MGTC delegates comprising Mr. Huzaimi (Director of Sustainable Mobility), Ms. Wan Nadia Kamarudin (Lead Analyst), and Mr. Hammad (Senior Analyst).

The official visit by MGTC was a continuation from the first meeting with UTM on 20th July 2020 where MGTC delegates visited the research facilities in the Centre of Hydrogen Energy at UTM Kuala Lumpur.

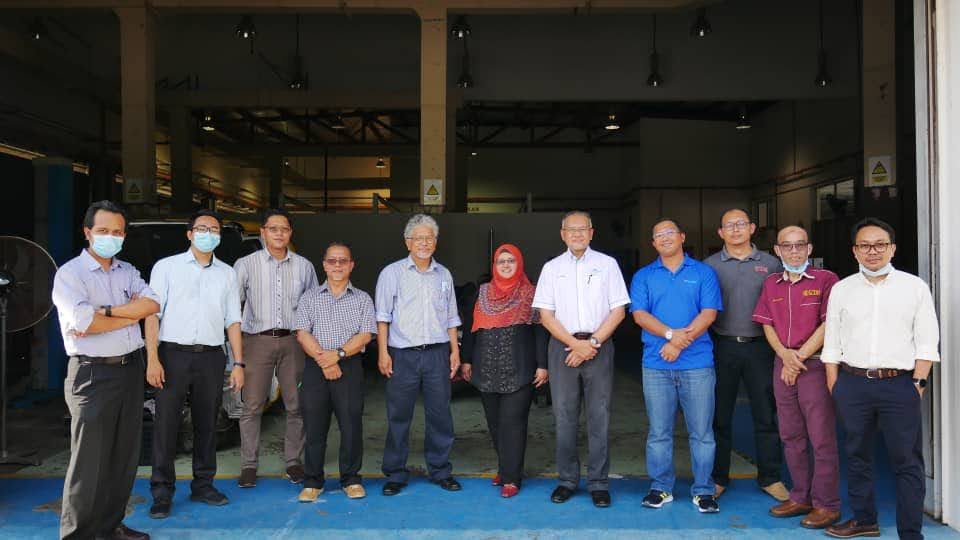

The meeting during the visit was chaired by the Director of the Institute of Future Energy, Prof. Dr. Arshad Ahmad by welcoming the presence of the MGTC delegates, followed by the brief research presentations from Assoc. Prof. Adnan Ripin (Centre of Hydrogen Energy (CHE) Director), Assoc. Prof. Ir. Dr. Md Pauzi Abdullah (Centre of Electrical Energy Systems (CEES) Director), Ir. Dr. Mohd Azman Abas (Automotive Development Centre (ADC) Director), and Assoc. Prof. Dr. Nik Rumzi Nik Idris (Head of UTM-PROTON Future Drives (UPFD) Lab).

From the left; Assoc. Prof. Ir. Dr. Md Pauzi Abdullah (CEES Director), Mr. Hammad (MGTC Senior Analyst), Ts. Mohd Fadhzir (IFE Senior Research Officer), Assoc. Prof. Adnan Ripin (CHE Director), Prof. Dr. Arshad Ahmad (IFE Director), Ms. Wan Nadia (MGTC Lead Analyst), Mr. Shamsul Bahar (MGTC CEO), Mr. Huzaimi (MGTC Director of Sustainable Mobility), Dr. Zulkarnain (ADC Research Fellow) and Ir. Dr. Mohd Azman Abas (ADC Director).

After the meeting, the visit was continued with a site visit to Electrochemistry Lab that headed by Prof. Dr. Aishah Jalil where all their researchers were focusing on the new synthesis and improved catalysts.

Then, the MGTC delegates visited the Hydrogen and Fuel Cell Lab, headed by Dr. Tuan Amran Tuan Abdullah where all the hydrogen and fuel cell research teams were conducting experiments there.

There was also a brief presentation by Ts. Mohd Fadhzir about the High-Temperature of Copper Chloride Electrolysis using Proton Exchange Membrane for Hydrogen Production to MGTC delegates.

MGTC delegates were also brought to the aquaponics projects where they can see and experience the integration of lobster farming, tilapia rearing and vegetable farming with the potential of using renewable and sustainable energy from solar modules. The aquaponics project was headed by Assoc. Prof. Dr. Anwar Johari from the Centre of Hydrogen Energy (CHE).

Prof. Dr. Aishah A. Jalil was explaining about the available facilities and the research that conducted in her Electrochemistry Lab to Mr. Shamsul Bahar (MGTC CEO)

Dr. Tuan Amran was elaborating the demo fuel cell set up in the Hydrogen and Fuel Cell Laboratory

Ts. Mohd Fadhzir was explaining the Operation of a High-Temperature Copper Chloride Electrolysis using Proton Exchange Membrane for Hydrogen Production to Mr. Shamsul Bahar, MGTC CEO

Assoc. Prof. Dr. Anwar Johari was showing the integrated aquaponic facilities to the MGTC CEO and delegates.

At UTM-PROTON Future Drives lab, MGTC delegates were presented with the latest development on electric vehicle car that involves a lot of research and hard work to develop an EV car prototype that can run 100% using the energy from battery storage.

The visit continued to the Automotive Development Centre (ADC) where the Research and Development (R&D) was focusing on the chassis, driving control dynamics, materials and cooling requirements developments.

The CEO and delegates of MGTC were very keen on the latest development in mobility and sustainable energy researches by our researchers and offered to have an extended Memorandum of Understanding (MoU) since there is already an MoU between Greentech Malaysia and UTM that focusing on human capital development signed previously.

Assoc. Prof. Dr. Nik Rumzi was showing and explaining the works done for the conversion of ICE engine to full EV car.

Dr. Zulkarnain was a very well versed and passionate about his research in automotive refrigeration and engine optimization

There will be something big coming out from the collaboration between the Malaysian Green Technology & Climate Change Centre (MGTC) and the Institute of Future Energy (IFE) in the near future especially towards the hydrogen fuel cell and sustainable energy research.