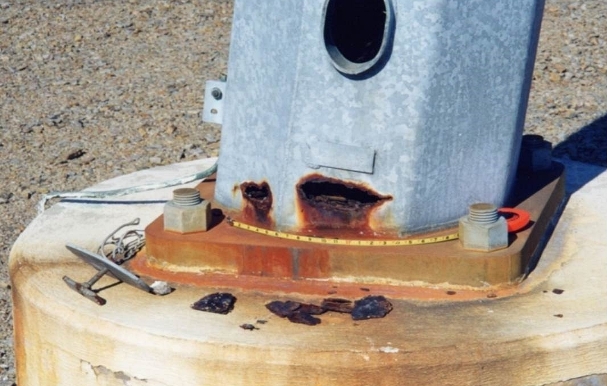

Mehrooz Zamanzadeh conducts a below-grade corrosion assessment of a buried tower leg. Photo courtesy of Mehrooz Zamanzadeh and BC Hydro Transmission.

Mehrooz Zamanzadeh conducts a below-grade corrosion assessment of a buried tower leg. Photo courtesy of Mehrooz Zamanzadeh and BC Hydro Transmission.

The electric power utility industry commonly uses galvanized steel for power transmission poles, lattice towers, and other transmission and distribution assets—particularly high-voltage transmission line structures and substation structures—because it is known to be well-suited for service in most atmospheric and underground environments and has a long record of proven performance. According to the American Iron and Steel Institute, close to 1 million steel distribution poles have been installed in the United States since 1998 and are being used by more than 600 U.S. electric utilities.1

Zinc galvanizing protects the carbon steel (CS) substrate by providing a barrier against corrosive compounds and also by acting as a sacrificial anode that protects the underlying CS surface if the coating is damaged. Adelana Gilpin-Jackson, P. Eng., a specialist engineer with Canadian electric utility BC Hydro (Burnaby, British Columbia, Canada) comments that hot-dip galvanizing provides electric utility structures with a surface layer (Eta layer) of pure zinc for galvanic and barrier protection, as well as several intermetallic zinc alloy layers (Zeta, Delta, and Gamma) that form as the zinc coating is applied under high temperatures. These layers are metallurgically bonded with the steel to form a tough and well-adhered coating that provides superior galvanic and barrier protection.

Galvanized structures typically exhibit a low corrosion rate because a continuous passive film, known as a zinc patina, forms on the pure zinc top layer of the galvanized surface when it is exposed to the atmosphere. This passive surface film provides a protective barrier that prevents moisture and chlorides from corroding the underlying steel. As the patina starts to develop, a layer of zinc oxide (ZnO) quickly forms as the zinc reacts with oxygen in the air. The ZnO layer, when exposed to moisture, converts into a thin layer of zinc hydroxide [Zn(OH2)], which reacts with atmospheric carbon dioxide (CO2) over time and becomes a dense, insoluble layer of zinc carbonate (ZnCO3) that slows corrosion of the underlying zinc.

Since zinc is anodic to steel, the hot-dip galvanizing also acts as a sacrificial anode if the galvanized coating is physically damaged to some degree. If individual areas of underlying steel become exposed, the surrounding zinc will provide sacrificial cathodic protection (CP) to the unprotected sites by corroding preferentially. The zinc is consumed as it sacrifices itself to protect the bare steel.

Generally speaking, galvanized steel can last for many years in nonaggressive environments, and typically does an excellent job of protecting steel when the structure is located in moderately corrosive environments where oxidizing conditions prevail, says Mehrooz Zamanzadeh, FNACE, a NACE-certified Corrosion Specialist. He notes that during a recent field assignment in Texas, galvanized lattice towers dating back to the early 20th century were observed to exhibit an intact galvanized layer even after 90 years of service.

Zamanzadeh emphasizes, however, that the galvanizing on structures will corrode over time. The rate that the thickness of the zinc coating will diminish and the length of the remaining service life of the galvanizing—and the structure itself—are contingent on the active corrosivity of the environment. Several factors are associated with the corrosion rate of galvanized structures, such as the in-service atmospheric conditions to which the aboveground portion of the structure is exposed, and the soil environment where the structure’s foundation is buried.

Atmospheric environments considered corrosive include marine environments with salt-laden air, and industrial environments, which can produce acid rain as a result of industrial activity. In soil, corrosion activity can be accelerated by the soil’s chemistry (i.e., the presence of moisture and corrosive ions), its level of electrical resistivity, stray currents, and the nature and surface areas of grounding materials. Accelerated underground corrosion can also take place in the absence of oxygen due to the presence of bacteria or acidic soils.

Other factors are also associated with corrosion of a galvanized steel structure, Zamanzadeh notes, such as improper galvanizing thickness, excessive brittleness of the intermetallic alloy layer, general galvanizing failure, poor substrate surface preparation (especially if it was previously coated), storage conditions, installation damage, and unsuitable protective topcoat selection for the in-service soil or atmospheric exposure conditions.

Because deterioration of the protective zinc coating can lead to damage of the underlying CS structure, corrosion is a concern for galvanized transmission and distribution assets since it can lead to weakening of the structure, and then failure or collapse, says Gilpin-Jackson. A corrosion risk assessment can determine the environment’s corrosivity and the associated corrosion risk to galvanized steel structures. When evaluating transmission and distribution infrastructure for corrosion, individual assets should be assessed in order of their structural priority. Existing corrosion damage noted in the assessments should consider, among other criteria, the structure’s age, location, past history, its importance in the power system, future plans for the structure, and the safety and financial consequences if the structure fails.

Assessing for In-Ground Corrosion

A significant portion of corrosion mitigation activities for transmission and distribution structures is focused on the embedded portion of poles and towers, notes Gilpin-Jackson, since the assets’ foundations are critical to their stability and continuing service. Because foundations for existing structures are buried and out of sight, they could be deteriorating and close to causing a structural collapse—without any traditional inspector being aware of the problem. Zamanzadeh adds that determining corrosion risk in the structure’s deep burial area (~6 to 8 ft [1.8 to 2.4 m] underground) is often missed due to lack of knowledge about corrosion risk assessment. “It is often the case that utility inspectors perform only minimal testing, such as visual inspection and coating thickness measurements, to a depth of 2.5 ft (0.8 m) below grade. Unfortunately, these practices fall short in determining the condition of deep buried structures where accelerated corrosion may be taking place. We were recently involved in a case with a collapsed tower due to accelerated corrosion in deep burial that could have been avoided if adequate corrosion risk assessment procedures were in place,” he comments.

Below-ground corrosion risk is primarily contingent on the amount of moisture and corrosive ions in the soil or outside interference. For example, when the soil is dry, its resistivity is generally high enough to inhibit corrosion; however, when moisture conditions change at a site, soil resistivity can be altered and corrosion may accelerate. Although galvanizing steel has considerable resistance to corrosion when buried, corrosion attack can be initiated in soils that are reducing, acidic, or contain large amounts of corrosive, water-soluble salts. Generally, terrain with lower resistivity and reducing properties promote higher corrosion rates; however, it is important to define the corrosivity of the environment to determine the type of corrosion mitigation required and how often maintenance is needed, Zamanzadeh says.

To determine the corrosiveness of a soil, different soil characteristics and relevant attributes of the physical environment should be considered. This type of assessment combines corrosion and materials science, metallurgy, and electrochemistry, and correlates them with the structure’s design features; and then quantitatively determines the environment’s physical characteristics so a multi-faceted, risk-based corrosion assessment can be done. Assessments include testing the soil environment to rate its corrosiveness; conducting visual and physical condition inspections of buried structural components at a shallow depth; and electrochemically testing the interaction between the soil and steel (i.e., potential values and soil resistivity) to predict structural corrosion at deep burial depths.

The test results can be used to assign a below-grade corrosion risk rating or condition assessment value to each structure, which takes the structure’s age, size, design, function, and importance into consideration. The ratings then can facilitate the development of suitable remediation and mitigation procedures. Zamanzadeh notes the confidence level of the risk assessment, which indicates the ability of the technique used to produce reliable corrosion risk data, depends on the scope of the evaluation performed.

Geographic information system (GIS) data with geological records that summarize soil parameters can be used to conduct a desk study (pre-assessment). Soil data collected should include classification, resistivity, corrosivity, and pH. Because the accuracy and reliability of this assessment is based on the GIS source data and doesn’t necessarily account for terrain shifts, this study carries a low confidence level.

Testing actual soil samples taken around the structures’ anchors and footings can measure the resistivity and corrosivity of the soil, which determines the soil’s capacity to act as an electrolyte, as well as identifies the soil’s corrosion performance parameters, which indicate how actively it will corrode the steel. This type of assessment can be used to estimate maximum galvanizing thickness loss and predict the structure’s life expectancy under the worst possible conditions. Since the accuracy of the assessment depends on the location of the soil sample, the condition of the instruments, and the inspector’s skill, this type of study has a moderate level of confidence.

Knowledge-Based Assessment

Both Gilpin-Jackson and Zamanzadeh note that a knowledge-based assessment evaluates the structure as well as defines the surrounding environment. Because all relevant corrosion and structural parameters are measured in addition to a visual inspection during the detailed assessment, the level of confidence in this type of assessment is high. Parameters reviewed in this type of assessment typically include the structure’s characteristics, configuration, and expected performance; the site’s features from a corrosion and materials point of view, including the atmospheric and soil characteristics; and other external influences present, such as alternating and direct current interference (e.g., stray current), the presence of grounding, other land uses, etc.

The galvanized structure is typically inspected visually to a below-grade depth of 36 in (0.9 m). If the structure shows significant signs of material loss at this depth, a more detailed condition assessment is performed using galvanizing thickness and adhesion measurements as well as defect characterization. Also, the maximum corrosion rate of the structural steel is measured using linear resistance polarization and electric resistance probes. Concrete inspection and petrographic analysis (if required) are performed for concrete base structures that are damaged or degraded.

“The knowledge-based assessment will let you know what mitigation techniques to use. Once you have all factual data, then you can make a recommendation—either implement corrosion mitigation, a repair, a replacement, or take no action,” Zamanzadeh comments. Additionally, he adds, the knowledge-based assessment can guide the inspection schedule for the structure so the scope of work over several years can be planned, funded, and staged.

Similarly, Gilpin-Jackson notes that owners want to be sure they invest upfront on corrosion mitigation for new structures that is appropriate for the in-service conditions. Because corrosion mitigation activities are increasing, so is the recognition that knowledge-based mitigation is vital.

Painting over galvanized steel transmission and distribution structures that have been in service for many years can extend the life of the zinc coating. For all cases where a structure is buried in corrosive soil, the galvanized steel should at least have a suitable topcoat applied to protect it against the adverse effects of higher-than-normal soil moisture/corrosivity, says Zamanzadeh. He recommends that a factory-applied, organic coating, such as polyurethane or other environment-resistant coating, be specified for galvanized steel structures in contact with corrosive soil. For more robust corrosion mitigation results, he suggests a CP system be added for each such structure, and notes this corrosion mitigation combination has proven to provide a stronger failure-safe solution than either a protective coating or CP alone.

Assessing and mitigating the corrosion before it causes a structural issue is vital. Monitoring the galvanized layer thickness will indicate the zinc coating’s remaining service life and provide a time guide for applying a protective topcoat. Typically, a structure won’t need to be topcoated until a significant portion of the galvanizing’s surface zinc is depleted, which could take 30 to 40 years depending on the service environment, says Zamanzadeh. Then, maintenance recoating should be considered when the galvanized steel’s top-most intermetallic galvanized layers—the Eta, Zeta, and Delta layers—are corroded. Generally, if the galvanizing’s Gamma layer (the layer closest to the substrate) is depleted, then structural corrosion may have initiated and it could be too late to paint without further steel assessment and possible steel replacement, notes Gilpin-Jackson. If structural corrosion is present, the load-bearing members may need to be replaced to protect the structure’s integrity. In extreme cases, the entire structure may need to be replaced.

Developing a long-term corrosion mitigation and maintenance plan based on a knowledge-based assessment can cost-effectively extend the life of galvanized steel transmission and distribution structures and prevent catastrophic failures. Plans should include future inspections, coating, CP, mechanical repairs, and other corrosion mitigation procedures where feasible.

More information on assessing galvanized steel for electric power utility transmission and distribution structures, including a case study that describes the application of a system-wide CP system for aging galvanized poles with below-grade corrosion, can be found in CORROSION 2016 paper no. 7245, “Galvanized Steel Pole and Lattice Tower Corrosion Assessment and Corrosion Mitigation,” by M. Zamanzadeh, C. Kempkes, D. Riley, and A. Gilpin-Jackson.

Contact Mehrooz Zamanzadeh, Exova—e-mail: zee@exova.com; and Adelana Gilpin-Jackson, BC Hydro—e-mail: Lana.Gilpin-Jackson@bchydro.com.

Reference

1 “Utility Poles,” Steelworks, the Online Resource for Steel, American Iron and Steel Institute, http://www.steel.org/the-new-steel/utility-poles.aspx (November 4, 2016).

Recent Comments