Cathodic Protection Design Calculation

5 Tips Hidup Tanpa Ropol – Perkongsian Terbaik Tuan Norizan

http://www.majalahlabur.com/kewangan/5-tips-hidup-tanpa-ropol/

Nickel-based Coatings May Slow Corrosion in Solar Power Plants

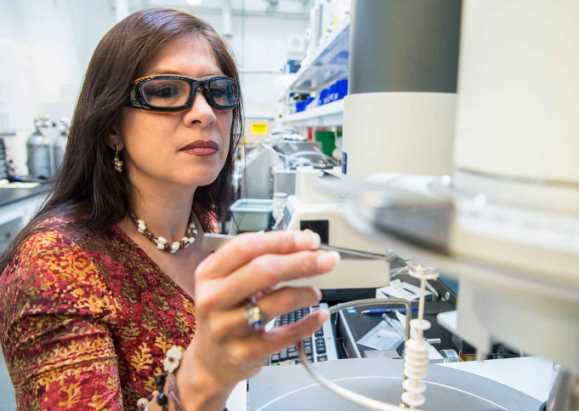

NREL engineer Judith Gomez-Vital examines several nickel-based coating options to reduce corrosion rates in concentrating solar power plants. Photo by Dennis Schroeder, NREL.

NREL engineer Judith Gomez-Vital examines several nickel-based coating options to reduce corrosion rates in concentrating solar power plants. Photo by Dennis Schroeder, NREL.

“We are very excited about the potential implications to provide corrosion-resistant coatings for CSP applications that could improve the economic viability,” says Johney Green, the NREL’s associate laboratory director for mechanical and thermal engineering sciences.

Problems with Molten Salts

To function, CSP plants require high-temperature fluids such as molten salts in the range of 550 to 750 °C to store heat and generate electricity. Molten salts mixtures containing sodium chloride (NaCl), potassium chloride (KCl), and magnesium chloride (MgCl2) are commonly used for both heat transfer fluid and thermal energy storage because they can withstand high temperatures and retain the collected solar heat for many hours.

At those high temperatures, however, the salts can eat away at common iron-nickel (FeNi) alloys such as Incoloy 800H (UNS N08810) and AISI 310 (UNS S31000) stainless steel (SS) used in the heat exchangers, piping, and storage vessels of CSP systems, the NREL explains.

To commercially use the molten salt mixtures, the corrosion rate must be slow—less than 20 μm/y, the NREL says—so that a CSP plant can achieve the projected 30-year service life for its containment materials.

By comparison, bare SS alloys tested in a molten chloride corroded as fast as 4,500 μm/y, the NREL says.

Nickel-based Solutions

To address this problem, NREL engineer and researcher Judith Gomez-Vidal began applying different types of nickel-based coatings, commonly used to reduce oxidation and corrosion, to the SS alloys. For her experiments, the 800H and 310 alloys were polished using abrasive paper until the surface was flat, and then machined to 8 mm in diameter and 12 mm in height. The nickel-based coating deposition was set up to have thicknesses of ~1 mm for electrochemical corrosion tests.

One such nickel coating, NiCoCrAlYTa, comprised of 23.0 wt% Co, 20.0 wt% Cr, 8.5 wt% Al, 0.6 wt% Y, and 4.5 wt% Ta, with the balance Ni, showed very strong performance. It limited the corrosion rate to 190 μm/y—not yet at the goal, but an enormous improvement compared to uncoated SS in the form of a 96% reduction in the corrosion rate.

That particular coating was preoxidized in air at 900 °C for 24 h with a heating/cooling rate of 0.5 °C/min. From there, metallographic characterization of the corroded surfaces using electron microscopy and imaging showed a uniform and dense layer of aluminum oxide (Al2O3) was formed before exposure to the molten chloride system. This, in turn, considerably reduced the alloy’s corrosion.

“The use of surface protection is very promising to mitigate corrosion in molten salts, in particular to those surfaces exposed to chlorine-containing vapor,” Gomez-Vidal says.

The corrosion evaluations were performed at 700 °C in a nitrogen atmosphere using a potentiostat. A Type-K thermocouple in an alumina well was used near electrodes to record temperatures, and the electrochemical cells were sealed and purged with nitrogen for about 24 h before corrosion testing.

Potentials were continuously recorded after the alloy’s immersion in the molten chloride, and polarization studies were conducted immediately after by applying cathodic and anodic external potentials. More than three coupons per test were performed under the same conditions to evaluate the consistency of the results.

“The chromium and aluminum in the coating were preferentially oxidized during preoxidation,” Gomez-Vidal says. “This oxide layer could help increase the corrosion resistance of the coatings. Alumina is a protective oxide with few defects in its structure, which minimizes or avoids the diffusion of elements. Thus, corrosion is controlled or mitigated.”

Further Rate Reductions Needed

Even with the 96% improvement in efficiency, the corrosion rate of 190 μm/y is still significantly more than the target of 20 μm/y or less needed for CSP plants to achieve a 30-year service life. As a result, more research is planned.

“The rates of corrosion are still considerably high for CSP,” Gomez-Vidal says. “This effort highlights the relevance of testing materials durability in solar power applications. More R&D [research and development] is needed to achieve the target corrosion level needed, which could include the synergy of combining surface protection with chemical control of the molten salt and the surrounding atmosphere.”

Further tests will require evaluation of the coatings under thermal cycling and the introduction of oxygen-containing atmospheres to increase the oxidation potential of the systems. The NREL notes that the addition of oxygen ensures the formation of protective scales that could reform in the presence of oxygen if cracks appear during operation.

Similarly, Gomez-Vidal says she has found other projects in which Al2O3 layers are able to form and remain adhered to the surface in the presence of air during thermal cycling of samples.

The research is funded by the DOE’s SunShot Initiative, which is a national effort to drive down the cost of solar electricity and support solar adoption. The program is aimed to make solar energy a low-cost electricity source through R&D efforts with both public and private partners.

The NREL is the DOE’s primary national laboratory for research and development on renewable energy and energy efficiency. The NREL is operated for the DOE by the Alliance for Sustainable Energy, LLC (Lakewood, Colorado) nonprofit group.

Source: NREL, www.nrel.gov. Contact Judith Gomez-Vidal, NREL—email:judith.vidal@nrel.gov.

References

1 “NREL Investigates Coatings Needed for Concentrating Solar Power,” NREL News Releases, Sept. 18, 2017, https://www.nrel.gov/news/press/2017/nrel-investigates-coatings-needed-for-concentrating-solar-power.html (Oct. 11, 2017).

Singapore water pipe bursts caused by corrosion

Bukit Batok water pipe bursts caused by corrosion: PUB

SINGAPORE: The two water pipe bursts in Bukit Batok last week were caused by corrosion in the pipes, the director of PUB’s water supply (network) department Michael Toh said on Wednesday (Oct 4).

Mr Toh was speaking during a site visit to Block 222, Bukit Batok East Avenue 3, where residents saw water shooting up several metres high at a carpark near the block after a water pipe burst last Sunday.

The incident came just days after a water pipe burst at Bukit Batok West, causing a three-storey-high geyser at a traffic junction.

The two leaks resulted in an estimated 7,580 cubic metres of water loss – roughly equivalent to three Olympic-sized swimming pools. About 7,500 cubic metres of water was lost from the first leak, and 80 cubic metres from the second.

As a result of the leaks, PUB will be conducting checks on all 100km of water pipes in Bukit Batok estate. Checks are expected to be completed by next week.

The agency will also replace the pipes in the vicinity of Bukit Batok Street 21, which are about 170m long, by December.

The second pipe at Bukit Batok East – which is smaller at 150mm in diameter -had two leaks on Oct 1 and one leak in 2012.

ACOUSTIC TECHNOLOGY TO TEST FOR LEAKS

Mr Toh explained that each kilometre of Singapore’s 5,500km of water pipes is checked at least once a year. The last time water pipes in the Bukit Batok estate were checked was in January, and no leaks were detected then.

“All our pipes are laid underground; so the challenge for us is how do we have a look underground,” said Mr Toh.

To test for leaks, PUB uses acoustic technology. Data loggers are temporarily attached to pipe valves, where they “listen” for increased noise – which may be an indication that a leak has occurred.

More sensors will also be installed in pipes to detect leaks.

Mr Toh added that PUB takes each incident seriously.

“Every leak is disruptive, and in Singapore’s context water is so precious to us,” he said.

Read more at http://www.channelnewsasia.com/news/singapore/bukit-batok-water-pipe-bursts-caused-by-corrosion-pub-9278262

8 Tips Terokai Pekerjaan Di Luar Bidang Pengajian

Menarik juga article yg zhsarer jumpa ni. Boleh baca keseluruhan article disini;

Positive Living

5 Habits for Positive Living

- Believe in yourself

- Help someone in need

- Live your passion

- Get daily inspiration

- Be honest

Please Watch Out!

Really and Excuse

If you really want to do something, you will find a way.

If you don’t, you will find an excuse.

Why Metals Corrode

The driving force that causes metals to corrode is a natural consequence of their temporary existence in metallic form. To reach this metallic state from their occurrence in nature in the form of various compounds (ores), it is necessary for them to absorb and store up the energy required to release the metals from their original compounds for later return by corrosion. The amount of energy required and stored varies from metal to metal.

Full article click Why Metal Corrode