The study was completed at Russia’s Trans-Siberian Railway, using an experimental facility for conducting induction and infrared thermal imaging. Photo courtesy of TPU.

The study was completed at Russia’s Trans-Siberian Railway, using an experimental facility for conducting induction and infrared thermal imaging. Photo courtesy of TPU.

Scientists from Tomsk Polytechnic University (TPU) (Tomsk, Russia) proposed a thermal imaging technique to study the corrosion of steel reinforcement within concrete railway pillars. The researchers say the nondestructive testing (NDT) method, which they tested in a recent study, enables efficient and quicker detection of corrosion hidden behind the concrete shell of the supporting structure.

“As the service life expires, the pillars become unfit for use with obvious negative consequences,” says TPU professor Vladimir Vavilov, head of the school’s research and development laboratory for thermal control. “It is impossible to replace all pillars simultaneously. Therefore, it is necessary to identify those that should be replaced first.”

“Ultrasonic testing is traditionally used for this purpose,” he adds. “Such testing takes up to one day. We propose thermal testing. Here, the process takes a few minutes and about an hour together with all preparation works.”

The mass electrification of Russian railways began in the 1980s, so the researchers’ study1is focused on railway pillars because those reinforced concrete poles are nearing their assumed lifetime of about 50 years. Thus, efficient inspection techniques to evaluate the concrete supports are expected to become increasingly important. The work was supported by a Russian Scientific Foundation grant.

Limitations of Traditional Methods

Pole damage often starts in the underground sections of supports, where corrosion initiates because of varying soil moisture and high mechanical stresses. Corrosion damage is often related to cracks that appear in concrete boundary layers adjacent to steel rebar. These cracks lead to the permeation of various corrosive agents, with chlorides being especially troublesome.

The corrosion defects are generally found under the concrete surface layer that is often hidden in the soil, thus making them visually undetectable, the researchers explain.

In addition to time inefficiencies, they say ultrasonic methods to detect corrosion—such as measuring ultrasound velocity in different directions, recording acoustic emission signals, or analyzing resonance features of the reinforcement—have limitations because they can only detect corrosion damage just prior to a pole’s failure. On the other hand, they say thermal techniques can “see” through the layers of a pole well enough to detect damage before failure.

While the researchers acknowledge classic thermal NDT techniques such as surface heating of test samples, they say this route is inappropriate for concrete poles because of the considerable pole thicknesses and the low thermal conductivity of concrete with regards to highly conductive steel.

As such, the researchers sought to develop a thermal heating technique that could be applied in the field, thus accounting for the unique properties of each pole.

In-Field Method Sought

After testing various thermal solutions on computer model simulations, the researchers decided their best option was to stimulate the metallic reinforcing steel by applying high-frequency inductive heating. Their goal was to detect any displacement of the reinforcement and better predict each pole’s residual strength.

When inductive heating is applied, they say infrared (IR) thermographic monitoring of the temperature distributions on the bottom 1- to 2-m section of a pole allows them to evaluate both the longitudinal and circumferential rebar reinforcement. Because the technique uses natural grounding, users only need to dig out the bottom sections of poles by about 0.5 m to allow direct IR surveying.

To test a pillar, an inductor coil is placed around it, which heats the steel reinforcement inside the pillar. It is applied to a narrow circular area on the pole surface, since the use of additional electrodes could damage any protective layers, such as coatings or linings, the researchers say. The inductor is powered at a rate of ~10 MW/m3 by an autonomous gasoline generator mounted on a nearby truck. This process is enough to heat the reinforcement a few degrees higher than the ambient temperature.

The heat radiated by the reinforcement is detected with IR cameras that are installed several m away from the pillar. By moving both the heater and IR camera for about 20 seconds, researchers say this allows them to gauge the pole’s temperature response under constant heating without putting too much stress on any one area. The technique is safe for personnel and fully nondestructive, since the excess pole temperature does not exceed 15 °C.

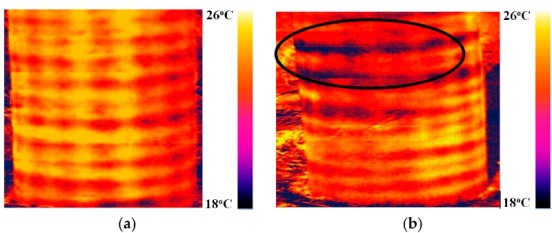

A thermogram, which shows temperature distribution at the tested surface, is transmitted from the cameras to a computer. Surface temperature signals in defect areas, characterized by high thermal resistance, may reach 3 to 10 °C depending on reinforcement depth, as well as rebar thinning and the presence of corrosion products. These defects diminish the rate of temperature changes by two to four times, the researchers explain.

“The fact is that the metal corrosion is most likely in the place contacting the ground,” Vavilov says. “In places already damaged by corrosion, the reinforcement is thinner. It is otherwise heated, which is displayed on thermograms. Up to the point, a thermal footprint disappears when air gaps and corrosion products occur.”

Pillar Findings Verified

The researchers tested their technique on 14 working pillars at the Trans-Siberian Railway in Russia’s Tomsk region, finding that two needed to be replaced due to defects associated with corrosion.

Because those two pillars were already near failure, the researchers were able to confirm their IR-based findings with ultrasonic and vibroacoustic testing. The ultrasonic and vibroacoustic tests came to the same conclusion, thus adding credibility to their method. Visual inspection of the underground pole sections also revealed some cracks and weak traces of corrosion products, the researchers say.

Further comparisons on the results of the IR thermographic surveys with the ultrasonic and vibroacoustic testing conducted on the same pillars will be discussed in a forthcoming paper.

Source: TPU, www.tpu.ru/en.

Reference

1 “Heat May Detect Invisible Damage in Railway Pillars,” TPU News, Feb. 13, 2018, https://tpu.ru/en/about/tpu_today/news/view?id=4014 (March 15, 2018).

Recent Comments