Today, first of the morning was fully occupied with intense brain focus to evaluate the MKH Master Safety project (9am to 1pm @ Bilik Dokumentasi). 7 students were evaluated by me and Dr. Kamarizan. At the same time, in parallel, 4 more MKH session were conducted in other venue.

Main scheduled tasks for week #1

3th Jan 2016 – Sunday :

4th Jan 2016 – Monday : MKH Master Safety Evaluation,

5th Jan 2016 – Tuesday : TTT Niosh Evaluation,

6th Jan 2016 – Wednesday : TTT Niosh Evaluation,

7th Jan 2016 – Thursday :

2 Certificates in 1 Week

It’s good to have some surprises once in a while rather than facing the same daily, weekly and monthly routine. Earlier this week on Sunday, I attended Citra Karisma 2015 where I became the finalist for the Webometric Award (Individual Category). There was no intention of winning since I started writing on this site since December 2014. It’s a rather young website to be regarded as finalist in this category. I am just happy to be one of the finalist and I was awarded a certificate of appreciation on my contribution for the Webometric Award. Yes, the winner was someone else. Still, I left Dewan Sultan Iskandar a happy guy.

It’s good to have some surprises once in a while rather than facing the same daily, weekly and monthly routine. Earlier this week on Sunday, I attended Citra Karisma 2015 where I became the finalist for the Webometric Award (Individual Category). There was no intention of winning since I started writing on this site since December 2014. It’s a rather young website to be regarded as finalist in this category. I am just happy to be one of the finalist and I was awarded a certificate of appreciation on my contribution for the Webometric Award. Yes, the winner was someone else. Still, I left Dewan Sultan Iskandar a happy guy.

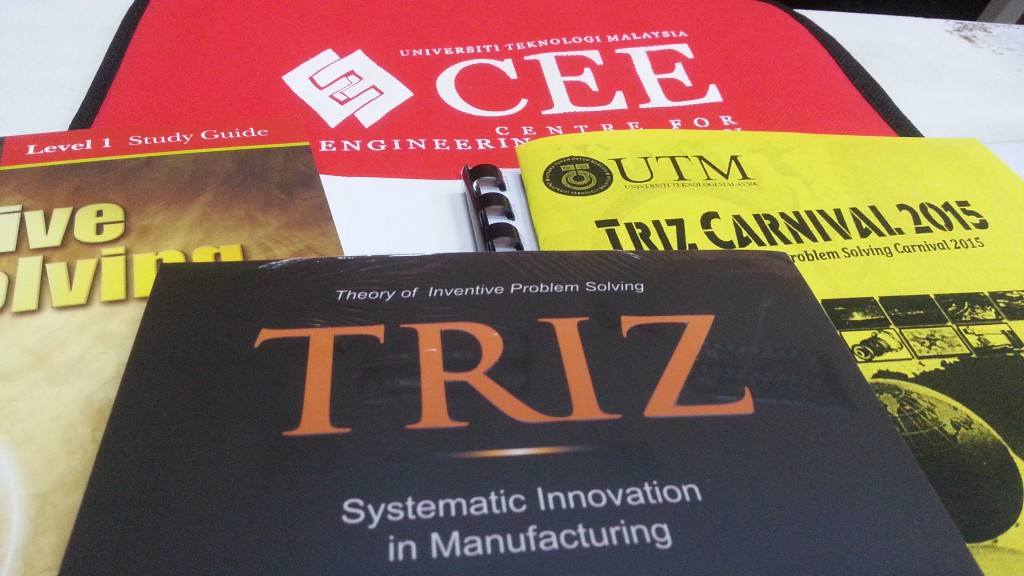

Then today, arriving early at work, I found another certificate in my pigeon hole. This time it’s a nice colourful beautiful certificate in front of me – “Malaysia TRIZ Certificate Practitioner”. It’s really great feeling getting all those certificate although in actual fact it is actually not a big deal. The cert is given to me after successfully passing the 1st level of TRIZ training in March 2015.

These 2 certificates will be later united with my other compilation of certificates. I may want to consider hanging some of them on the walls. What do you think?

5th International Conference of Fuel Cell and Hydrogen Technology 2015 (ICFCHT2015)

Check this out. I highly recommend you to participate in this conference… I have submitted my abstract. How about you?

As one of the most versatile energy solutions ever invented, fuel cells are able to generate clean, efficient and reliable power for almost any device requiring electricity and because of that, it has significant roles to play in a number of energy end-use sectors from electric vehicle to power plant. In the near future, fuel cell will power our cars with hydrogen replacing the petroleum fuel that is used in most vehicles today.

Believing in the bright future prospects of hydrogen and fuel cells, we take a great pleasure to organize and to cordially invite you to attend the 5th International Conference of Fuel Cell and Hydrogen Technology 2015 (ICFCHT2015) on 1-3 September 2015 at UTM Kuala Lumpur.

For more details regarding the conference, please visit the conference website. Those interested to present a paper in the icfcht2015 are required to submit a softcopy of an abstract by uploading the abstract in the REGISTRATION FORM no later than 15 May 2015. For the preparation of your abstract please use the abstract template.

If you have any questions, please do not hesitate to contact us. Your presence at this conference is important to us. We look forward to seeing you there.

Link for you to see: http://www.icfcht2015.utm.my/

TRIZ Level 1 Workshop

The Center Of Engineering Education (CEE), Universiti Teknologi Malaysia (UTM) has recently conducted a very excellent program, “2-Day Level 1 TRIZ workshop and Forum on Complex Problem Solving from Industries’ Perspective“. It was conducted from 30 March to 1 April 2015.

What is TRIZ?

TRIZ is “a problem-solving, analysis and forecasting tool derived from the study of patterns of invention in the global patent literature”. It was developed by the Soviet inventor and science fiction author Genrich Altshuller and his colleagues, beginning in 1946. In English the name is typically rendered as “the theory of inventive problem solving”, and occasionally goes by the English acronym TIPS.

Following Altshuller’s insight, the theory developed on a foundation of extensive research covering hundreds of thousands of inventions across many different fields to produce a theory which defines generalisable patterns in the nature of inventive solutions and the distinguishing characteristics of the problems that these inventions have overcome.

An important part of the theory has been devoted to revealing patterns of evolution and one of the objectives which has been pursued by leading practitioners of TRIZ has been the development of an algorithmic approach to the invention of new systems, and the refinement of existing ones.

The theory includes a practical methodology, tool sets, a knowledge base, and model-based technology for generating new ideas and solutions for problem solving. It is intended for application in problem formulation, system analysis, failure analysis, and patterns of system evolution.

Source Wikipedia.

Outcome from the Level 1 TRIZ Workshop

It was a very interesting 2 days workshop. I must admit all of us who attended learned massively a lot. Most importantly, we were given the Level 1 TRIZ test to measure and evaluate our fundamental knowledge on TRIZ. The good thing is I passed the Level 1 TRIZ test… 🙂

Dr. Yeo T.S., our very experienced trainer for the 2 days TRIZ wokshop. He is one of the TRIZ master in Malaysia

Should there be a level 2 TRIZ that I can attend, I will surely attend and if I passed the Level 2 TRIZ, I can become a Level 1 TRIZ trainer.

The 3rd day of the program, a very productive forum, Forum on Complex Problem Solving from Industries’ Perspective, was held at T02 CEE building. Numerous panels from industry were present to share inputs and ideas with regard to complex problem solving and its relation to university graduates capabilities and how to improve our graduates skills in solving industrial complex problem. In overall, it was a very good program indeed and such program must be conducted annually and to proceed with higher levels of TRIZ workshop.

New publication for 2015 – Energy Journal

This is a great opening for 2015. One of our journal paper was finally published in Energy journal. The impact factor for this journal is 4.159. The title of the publication is “The challenges and prospects of palm oil based biodiesel in Malaysia“. I would like to thank all authors especially Dr. Anwar Johari and Ir. Bembga Bevan Nyakuma for such a splendid work.

eLPPT 2014 – Rush hour time

For any employers working in any organization regardless of private or government, he or she could not escape the yearly performance assessment or evaluation process. Me too, included. We, academic staffs are assessed via a platform called eLPPT. Not sure what that stands for (for now ~ will check later).

We need to record all of our tasks, jobs, teaching, research, writing… everything you name it…that we lecturers have to do.

Read related post such as Welcome to my site.

Final Classes for the semester end

This semester I teach (a) Introduction to Engineering for 1st year student and (b) Engineering Economics and Project Management for final year students. It has been quite a semester for this past 4 months. But I am happy everything works perfectly fine. I hope the students benefit the most from me… I hope.

And as usual, on the final day of the semester, we will have this special photo session, that will be cherished as fond memories.

With students from my Introduction to Engineering Class ~ final day in class (click to enlarge)

With students from my Introduction to Engineering Class ~ final day in class (click to enlarge)

With students from my Engineering Economics and Project Management Class ~ also final day in class (click to enlarge)

With students from my Engineering Economics and Project Management Class ~ also final day in class (click to enlarge)

Read related article such as Best of the best award at iPHEX 2014.

Board of Engineers Malaysia extended my Professional Engineer status for 2015

Today, I just received the new certificate of professional engineer membership renewal from Board of Engineers, Malaysia (BEM). I solute BEM big time because it processed my membership swiftly and smoothly. Everything was done online, CPD record, payment and registration. Well done BEM!!!