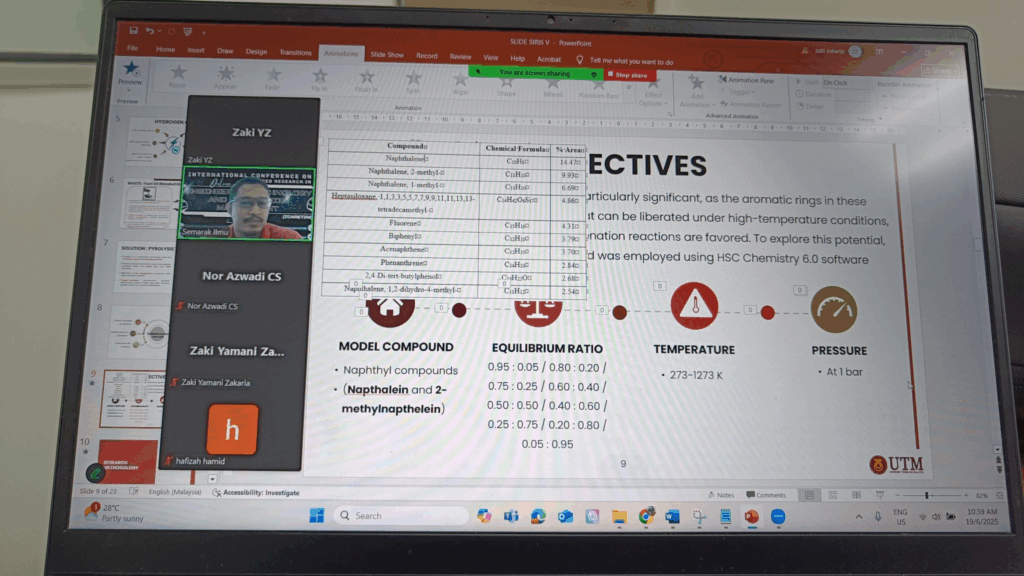

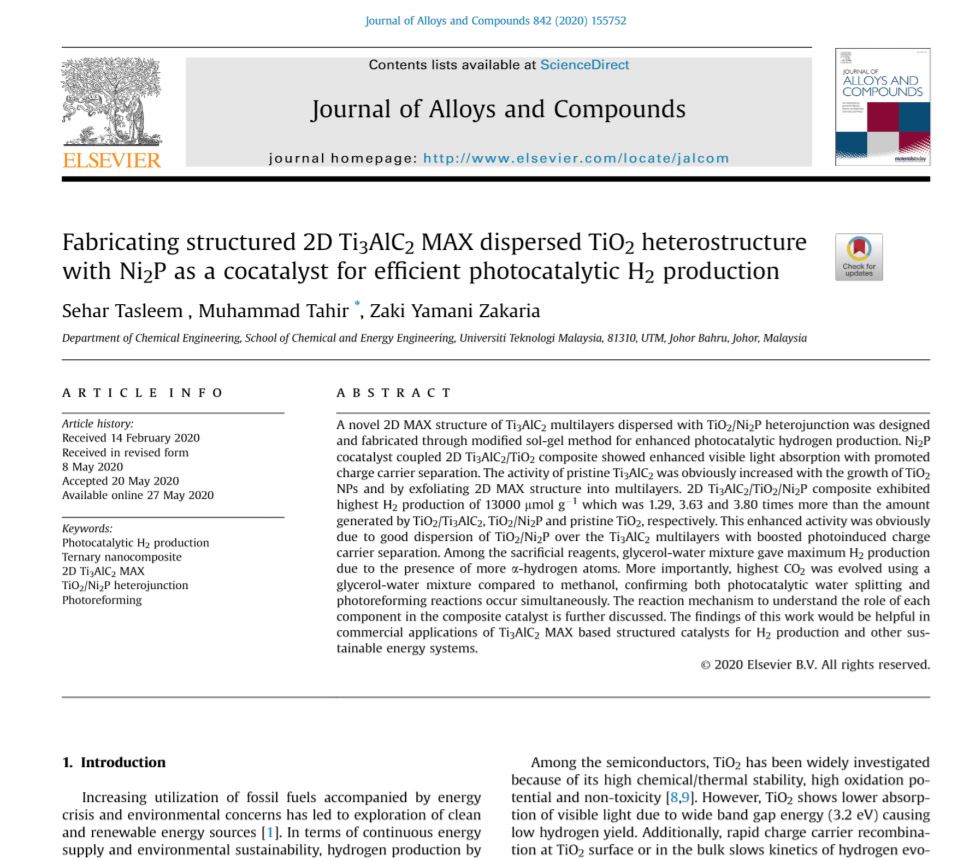

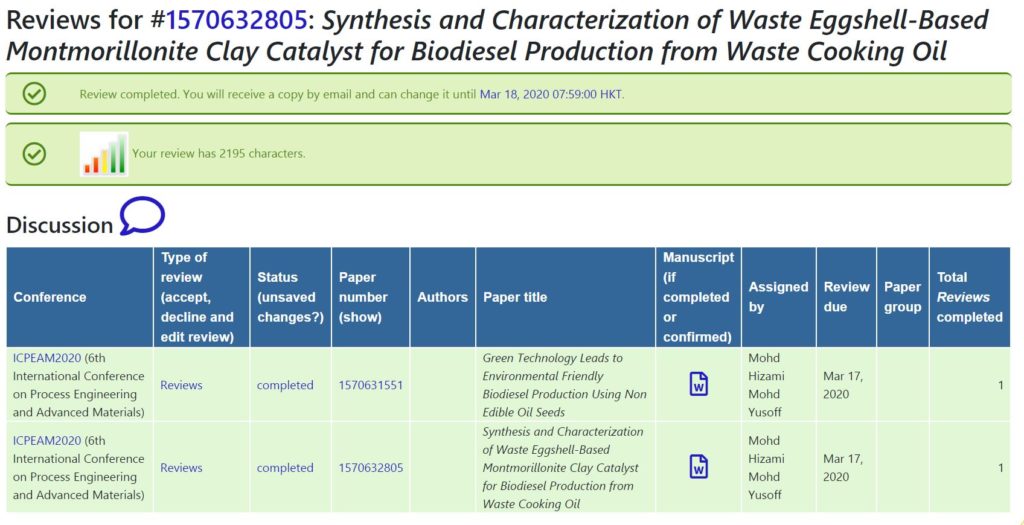

Amid the discussion with HiCOE IKG this morning, I asked for permission to step out briefly as I had to present a keynote at a conference. Thank you to Anis Amira Wan Ranizang for helping to prepare the slides and paper for the conference. Luckily, everything was conducted online, and thank you to IKG for lending me a room so I could deliver the keynote comfortably.

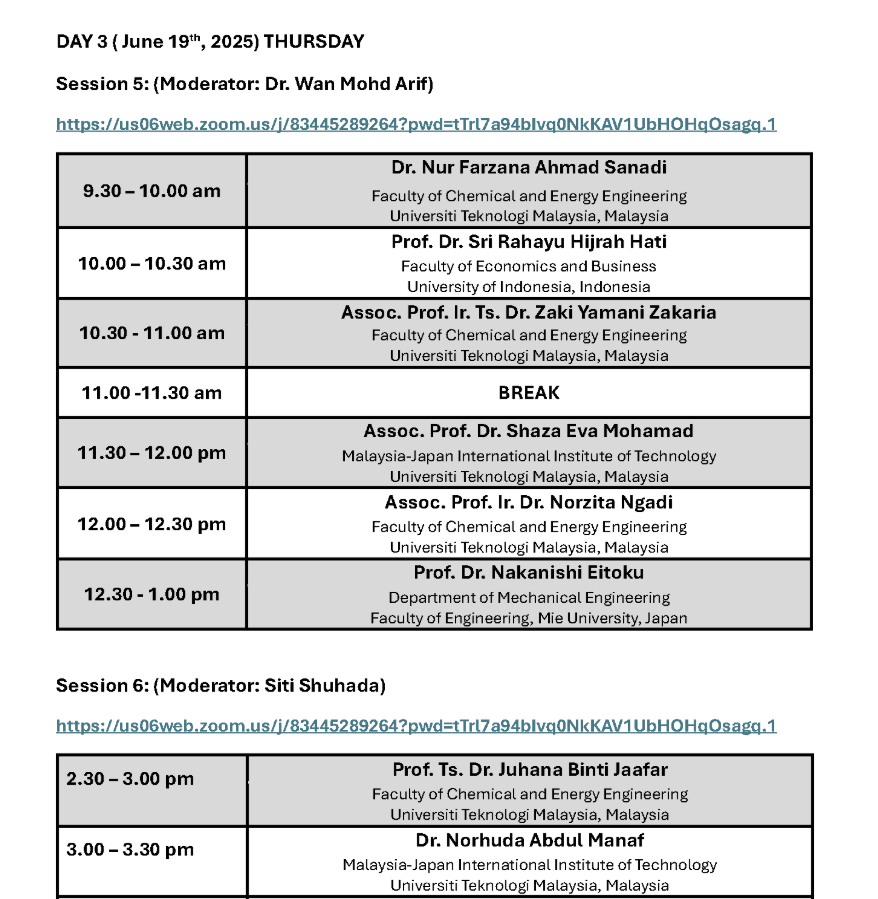

Here is the Tentative Schedule: https://semarakilmu.com.my/journals/index.php/ICARETIM2025/Program_Schedule