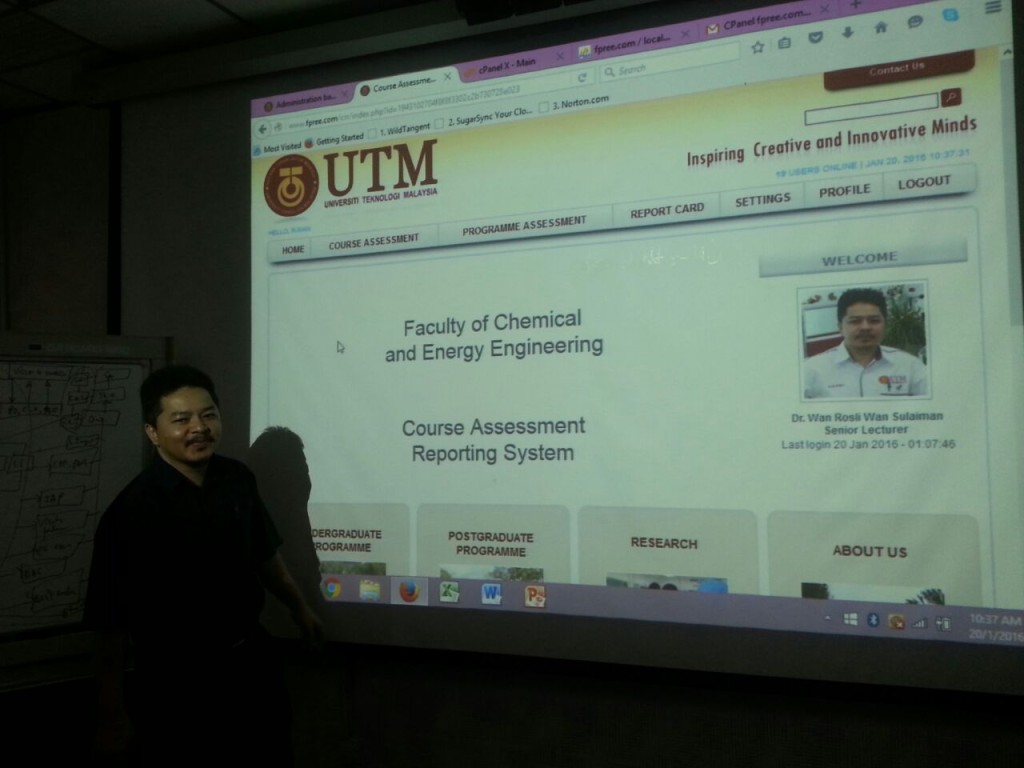

Following are Week 1 to 2 notes for MKH Master Safety – Industrial Hygiene.

Week 1 => Housekeeping & Physical Arrangement

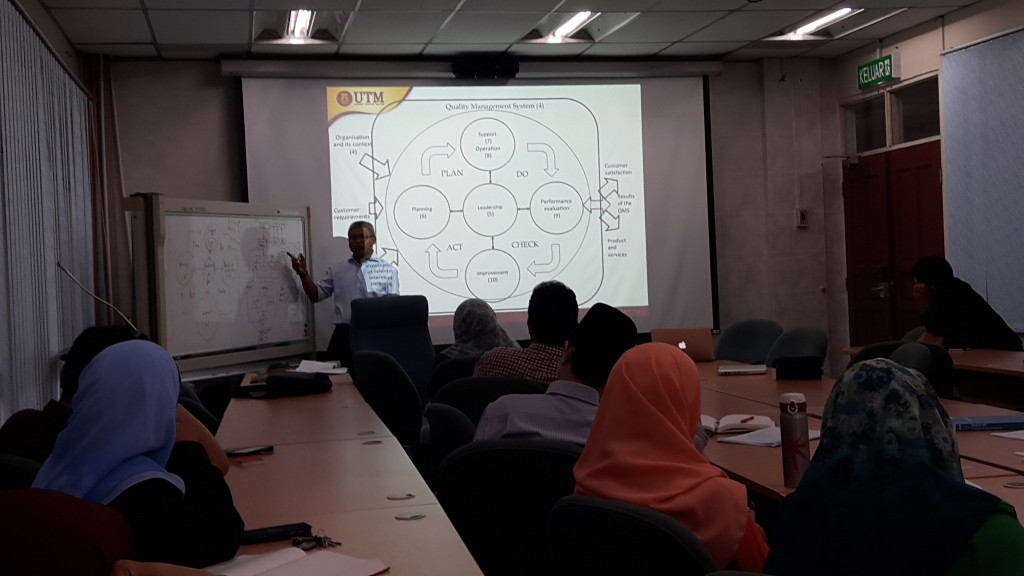

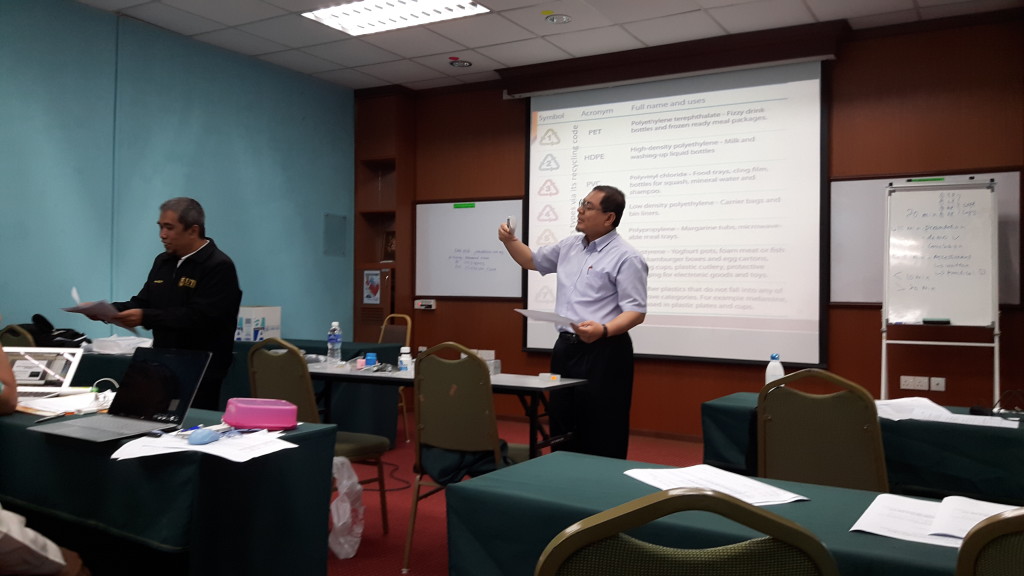

Week 2 = > (a) Machinery-Hazard (b) HIRARC Training

Week 3 = > (a) Machinery Protection (b) Safe Machine Operation

Disclaimer – This notes are for learning purpose only and are not permitted to be distributed or republish anywhere.

Good luck 🙂

For Slides from Week 4 to 7, please click here.